Since the discovery of carbon nanotube (CNT)1, exploitation of its application is sought in all possible arena of life and role of CNT in biological systems and medicine is highly important and these area needs newer approaches to do so. For the biological application the important task to make CNT first fairly water soluble is crucial. We have made a simple approach to achieve that and started using water soluble CNT 2 as probe in different biological aspects. The present study deals with its effect on the growth of gram C. arietinum seed under different concentrations of wsCNT.

There are many reports of ingesting of single wall carbon nanotube in macrophage cells without showing any toxic effect3. Gas and water flow measurement through micro fabricated membranes in which aligned CNTs having diameters less than 2 nm served as pores to show that the gas and water permeability of nanotube based membranes were several orders of magnitude higher than those of commercial polycarbonate membranes4. Molecular dynamic simulation on osmotically driven transport of water molecules through hexagonally packed carbon nanotube membrane were simulated in relevance to CNT semi permeable membrane to separate components of pure water and salt solution5. Molecular dynamics simulation of flows of water inside CNTs was also studied6 . However, experimental findings on such phenomena are lacking. Molecular transport across cellular membranes is essential to many of life’s processes. In the molecular life, water and minerals are essential components for growth and their transport to different cells and organs are critically important for survival of a living entity. In vascular plants, root helps plant in transport of water and solutes7 and involved in pumping of water across the plasma membrane into the cytoplasm of cells8 . Pumping of water is due to the water potential caused by the transpiration. We used dicotyledonous plant of gram – C. arietinum seed as it has a very short life cycle, and its vascular bundles are arranged in ring in comparison to monocotyledonous plant in which the vascular bundles are scattered. The growth of gram C. arietinum seed were observed under different concentrations of wsCNT; and it was found that the plant grown in solution having maximum concentration of wsCNT showed maximum growth.

Materials and Methods

Water soluble multiwalled carbon nanotubes (wsCNT) wsCNT which were synthesized as by the prescribed method with slight modification from the previous method2 like standing the carbon soot in concentrated nitric acid overnight and decanted off the sample to remove excess of acid and the black mass was washed with distilled water several times till it was neutral. At the final stage of washing, decantation resulted loss of materials and so the residual water was removed under boiling water bath. Repeated adding water and evaporation under boiling water bath removed trace amount of volatile nitric acid and the nitrate free final wash has been tested using Griess reagent9 . The black residue was finally vacuum dried (300 mg) and subjected to analysis. The highly cabroxylated CNT (wsCNT) thus formed became readily soluble in water under sonication and remained in solution for months without precipitation.

Seeds

eeds of common gram C. arietinum were kept in a dry place in the dark under room dark under room temperature before use. Sprouted (one day) gram seeds were grown in different concentrations of wsCNT (a stock of wsCNT with its concentration 1.45gm /liter was used after sonication to dissolve).

Germination

Seeds were immersed in a 10% sodium hypochlorite solution for 10 min to ensure surface sterility (USEPA, 1996), then, they were soaked in DI-water for germination for one day. Then, sprouted one day gram seeds were then transferred onto the sample vials, which were grown in different concentrations of wsCNT. After 13 days, growth in different parts of the plants like shoot and roots were observed

For Fluorescence

Stock solution of 0.009 gm wsCNT and 0.001 gm CdSO4, (0.004 mmol) (purchased from Sigma Aldrich) was prepared in 10 ml double distilled water and refluxed for 3.5 hrs followed by stirring for 1 hour. Ammonium sulphide was prepared with 25 ml NH4OH in which H2S was passed for 1 minute. 300 µl stock solution was taken in vial 1ml water, into which 1-2 drops of ammonium sulphide was added, to the transverse section (T.S.) and lateral section (L.S) of root. Slides were then prepared and watched under fluorescence microscopy. Ammonium sulphide addition is a necessary step as it converts the CdSO4 into CdS which in turn fluorescence the channel made by wsCNT. After two hours of this exposure, the solution mixture was removed and the root part of the sprouted seed was washed with running distilled water to free it from external CdSO4. The washed sprouted seed root was now dipped into 2ml of distilled water pre-saturated with H2S gas. After 30 minutes, the entire sprouted seed was washed with running distilled water and slides were then prepared from the T.S section of the root. Florescence microscopic images of CdS incorporated into wsCNT showed very distinct tubular structures due to the fluorescence of CdS inside the wsCNT. The excitation wavelength used was 371 nm.

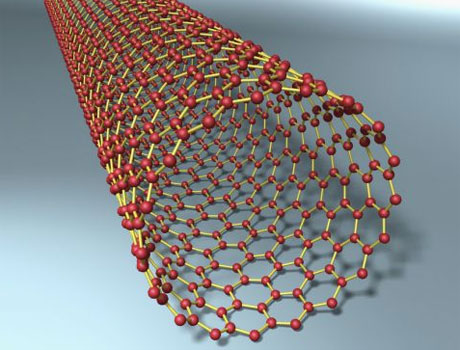

In this study, we report the comparative growth of sprouted (one day) gram seed in the presence of different concentrations of wsCNT in comparison with controlled one, which were imaged by Scanning electron microscope (SEM) equipped with an energy-dispersive X-ray analysis and were recorded with FEI Quanta 200 Hv and “Tecnai 20 G2” 200 kV STWIN used for Transmission electron microscopic (TEM) analysis (Figure 1).

Figure 1 -(A) Scanning electron microscopy image having the scale bar of 5µm; (B) its EDAX analysis showing the presence of carbon and oxygen only; (C) Transmission electron microscopy scale bar 100 nm; (D) High Resolution transmission electron microscopy (inner diameter approx 12 nm) having the scale bar of 5 nm.

To compare the growth in different parts of the plants like shoot and roots, three different sets of five vials were used. In the first set, seeds were grown under controlled condition in the second set 100µl wsCNT solution is added in 5ml double distilled water ; in the third set of vials the concentration of the wsCNT is 200µl wsCNT in 5 ml double distilled water . And for comparison the water level; shoot length, root numbers and root length were observed for 13 days (Figure 2).

showing the comparative growth of gram plants in controlled, 100µl and 200µl wsCNT solution . Comparing the size of wsCNT (10-30 nm) shown in (Figure 1) and xylem (few microns), it can be assumed that the CNT capillary structure may get introduced inside the lumen of treachery elements since the size difference between these two, drifts wsCNT to be incorporated within the xylem according to the concept of the formation of a “large capillary”. This is formed inside the treachery elements of the xylem by head to tail arrangement of one carbon nanotube to the second and thus it provides channelling through which water is conducted. Carbon nanotube thus providing channels through which water can be conducted (Figure 3).

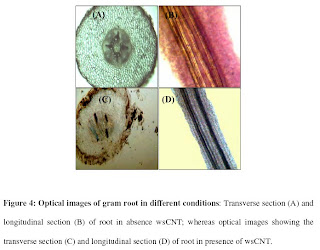

Here in, effects were observed that wsCNT which were initially in the form of cluster aggregates like spaghetti; get aligned in the vascular bundle due to endo-osmotic root pressure caused by xylem10. These vascular bundles run all through the plant and consist of xylem and phloem. Alignment of carbon nanotubes within the treachery elements of xylem has been established by optical microscopy (Figure 4) from the wsCNT treated sprouted gram seed Florescence microscopic images of CdS incorporated into wsCNT showed very distinct tubular structures due to the fluorescence of CdS inside the wsCNT. The excitation wavelength used was 371 nm. The presence of wsCNT in the plant root (especially in the xylem) can be detected by the images obtained from optical microscope shown

(Figure 4) in the absence and in the presence of wsCNT.

(Figure 5) clearly showed the channels fluoresces through the passage of Cd+2 ion subsequently exposed with sulfide to precipitate fluorescing material CdS. To understand the mechanism, inducing growth of the plants, it might be possible that wsCNTs after attaching with the root surface or inner portion of root (such as vascular bundles, cortical region etc.) enhances the capillary action of water absorption as shown by simulated work5,10. Our present work suggested that water is not only occupies these channels but also molecular transport takes place faster inside the plant via xylem where wsCNT acts as membrane that offers both high selectivity and high flux. This consequences almost frictionless and very rapid flow, and the transport is predicted by molecular dynamics, which correlates this enhancement of flux to atomic smoothness of the nanotube surface and to molecular ordering phenomena that may occur on confined length scales in the 1-2 nm range 6 . In atomically smooth pores, the nature of water–wall collision can change from purely diffuse to a combination of Specular and diffused collisions leading to the observed fast transport. This faster transport of water leads to high absorption of water by the roots containing nanotube in the xylem resulting increased length of root, shoot, and root hairs which ultimately increase the productivity. It might be possible that after being adsorbed within the root surface (mainly root hair region) carbon nanotubes retard the salt uptake by making xylem tracheids less porous. As a result of less porosity, it permits the uptake of only small molecules by xylem tracheids where as large molecules became unable to pass through CNTs.

The rate of the survival of the plants (under laboratory condition) grown in CNT solution is more than the plants grown in distilled water only. In the first table it is shown that out of five plants only two plants survived, plants grown with 100 micro liter CNT solution three plants

survived and the plants grown with 200 micro liter CNT solution out of five plants four plants survived, by the end of experiment. The water absorption rate by the plants in the vials containing wsCNT was more than the plants grown in distilled water only. Plants grown in distilled water showed least water absorption, while plants grown with CNT were found to absorb more water and the depletion in water level is more in these vials. The root system of the plants grown with CNT was found to be more branched. The root length (the longest branch of the root) is longest of the plants grown in CNT